Continuous Countercurrent Reactor (CCR) Innovation

The PureVision Technology is the heart of a biorefinery that converts diverse cellulosic feedstocks into pulp, lignin and sugars, all intermediate materials for creating thousands of biobased products. PureVision collaborators, biorefinery partners and downstream processors will convert the pulp, lignin, and sugars into different industrial and consumer products in separate, but integrated biorefinery unit operations.

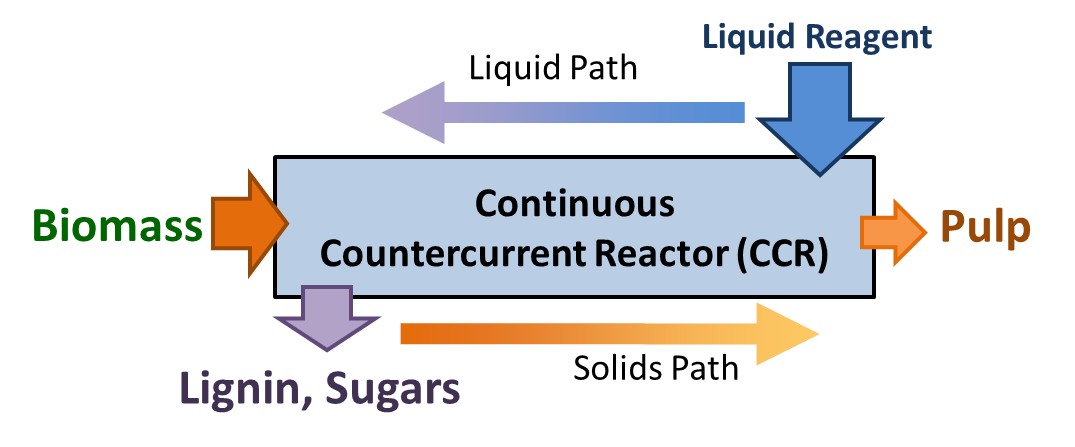

PureVision’s patented CCR and proprietary process chemistries rapidly deconstruct biomass into its essential elements. The CCR utilizes a modified extruder to break down biomass into intermediates for downstream conversion to paper products, fermentable sugars, chemicals, nutraceuticals, plastics and many other consumer and industrial biobased products. Countercurrent processing of biomass, where biomass moves in the opposite direction (in counterflow) of the reagent liquid, allows for highly effective reactions within the CCR, producing high-quality pulp, lignin, and sugars in minutes. The technology has enormous versatility and flexibility due to the countless processing variables that can be achieved with countercurrent processing.

The PureVision Technology is feedstock agnostic. PureVision has undertaken research and development with corn stover, wheat straw, triticale straw, sugarcane bagasse, hard wood varieties and industrial hemp.

The PureVision Technology separates the primary constituents of cellulosic biomass into three product streams: a solid cellulose fraction (pulp), lignin and xylose-rich liquor. Because of the high purity of the cellulose fraction, it can be sold as a pulp for papermaking, upgraded to a wide variety of products such as alpha cellulose, nano cellulose and dissolving pulp or hydrolyzed into glucose to make chemicals, plastics, and fuels.

Lignin is the binder found in all plants giving them strength and rigidity, and makes up 15-25% of all biomasses. PureVision’s lignin has been tested in both client and 3rd party laboratories, and unlike conventional lignin produced by the pulp & paper industry, the PureVision lignin has shown to have outstanding and unique qualities, suitable for producing value-added industrial products including graphene, carbon fibers, plastics, coatings, and specialty chemicals.

The xylose-rich (sugar) liquid fraction has proven to be very fermentable and can also be further processed or conditioned and used as the primary raw material for making many industrial and consumer products, including xylitol.

There are three major steps in converting abundant cellulosic biomass into product streams in the emerging biorefining industry. The first step involves growing, harvesting, baling, storing, and transporting biomass to a biorefinery. The second step involves the conversion of the biomass into pulp, lignin and sugars using the PureVision Technology. The third step is the conversion of these intermediate biomaterials into industrial and consumer products. The PureVision platform focuses on the second step, leaving steps one and three to others.

PureVision also has the expertise to conduct bench-scale and pilot-scale studies to convert untested biomass feedstock(s) into product streams. Once a specific set of operating conditions is determined, PureVision and 3rd-party engineers conduct process and economic modeling.

The PureVision Technology is disruptive because unlike current commercial-scale technologies, it economically and rapidly converts raw biomass into pulp, high value lignin and sugars while substantially reducing environmental impacts.